Lekce 1: Piston Pumps

Kapitola 1: Piston Pumps

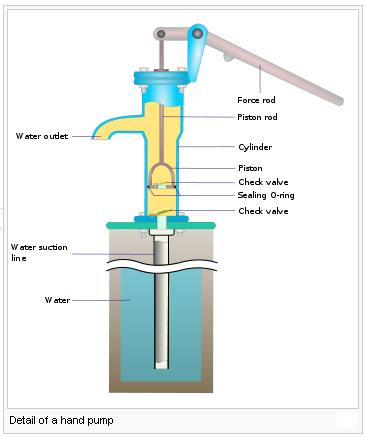

Piston pumps are a type of water pumps which cause the liquid to flow using one or more oscillating pistons.

Piston pumps belong among the reciprocating pumps. They need a system of suction and dischargevalves, thanks to which the fluid is moved in a required direction. There are various types – some of them have just one cylinder (called simplex-cylinder pump), others may have up to four cylinders (quad-cylinder pump) or even more. Most reciprocating pumps are duplex- or "triplex-cylinder types (with two or three cylinders).

Types according to the way of suction and discharge

Piston pumps can also differ according to the direction of suction and discharge.Single acting piston pumps have independent suction and discharge strokes, while double acting pumps perform suction and discharge in both directions.

Application

Piston pumps are usually driven by air or steam, or by a belt drive from an independent engine. Piston pumps were very popular in the times of the industrial revolution in the 19th century, but nowadays they are used less often. Their usual application is for pumping fluids with high resistance, where high flow rate is not needed. Typical pumped materials include for example concrete and heavy oils.

Vocabulary

Piston pump – pístové čerpadlo

Piston – píst

Liquid – kapalina

Flow – téct

Cylinder – válec

Suction valve – sací ventil

Discharge valve – výtlačný ventil

Fluid – tekutina

Independent – nezávislý

Stroke – doba, zdvih pístu

Perform – provádět

Driven – poháněný

Steam – pára

Belt drive – pásový pohon

Industrial revolution – průmyslová revoluce

Application – použití

Resistance – odpor

Flow rate – rychlost toku, průtoková rychlost

Concrete – beton

Oil – olej

Obrázky a fotografie použité v této kapitole pochází ze stránek {Wikimedia Commons XH http://commons.wikimedia.org}, kde byly zveřejněny pod licencí {GNU FDL XH http://commons.wikimedia.org/wiki/Commons:GNU_Free_Documentation_License}.

Kapitola 2: Cvičení

- Studenti zpracují na téma Piston Pumps powerpointovou prezentaci.

Kapitola 3: Kontrolní otázky

- Can you briefly describe piston pumps?

- In what ways can they be divided?

- What are some typical materials, which are pumped by piston pumps?

Kapitola 4: Autotest

- How many pistons do piston pumps have?

- How many cylinders does a quad-cylinder pump have?

- Which type of pumps have independent suction and discharge strokes?

- Which type of pumps perform suction and discharge strokes in both directions?

- Piston pumps are used

Lekce 2: Piston Compressors

Kapitola 1: Piston Compressors

Description

Piston compressors (often also called reciprocating compressors) are a type of positive-displacement compressors, driven by a crankshaft. They convey gases at high pressure. The intake gas flows through the suction manifold into the compression cylinder. Here a piston, which is driven by a crankshaft, compresses the gas, which is then discharged.

Application

Reciprocating compressors are used in many kinds of industries. We can find them in gas pipelines and natural gas processing plants, oil refineries, chemical factories and refrigeration plants. Plastic bottles made of polyethylene terephthalate (PET) are also manufactured by blowing with the use of piston compressors.

Piston compressors can be made as a portable tool, which can power various machines. In the past they were used to drive for example pneumatic drills. Such a unit was usually mounted on a trailer and the compressor was driven through a centrifugal clutch by an engine, usually diesel. The engine had a speed limiter (or a governor), which enabled it to run at two speeds:

- idling, the clutch was disengaged

- maximum, the clutch was engaged and the compressor was running

Vocabulary

piston compressor, reciprocating compressor – pístový kompresor

positive-displacement compressor – objemový kompresor

driven – poháněný

crankshaft – kliková hřídel

convey – dopravit

pressure – tlak

intake gas – nasávaný plyn

suction manifold – sběrné sací potrubí

compression cylinder – vzduchový válec

piston – píst

compress – stlačit

discharge – vytlačit

application – využití

industry – průmysl

gas pipeline – plynovod

natural gas processing plant – továrna na zpracování zemního plynu, plynárna

oil refinery – ropná rafinérie

refrigeration plant – chladící zařízení

polyethylene terephthalate – polyethylentereftalát

blowing – vyfukování

portable – přenosný

tool – nástroj

power – pohánět

pneumatic drill – pneumatická sbíječka

unit – stroj, agregát

mounted – upevněný, namontovaný

trailer – přívěs

centrifugal clutch – odstředivá spojka

diesel engine – naftový motor

speed limiter, governor – omezovač otáček, omezovač rychlosti

idling – volnoběh

engaged clutch – zapnutá spojka

disengaged clutch – vypnutá spojka

rotary compressor – rotační kompresor, kompresor s otočnými písty

Obrázky a fotografie použité v této kapitole pochází ze stránek {Wikimedia Commons XH http://commons.wikimedia.org}, kde byly zveřejněny pod licencí {GNU FDL XH http://commons.wikimedia.org/wiki/Commons:GNU_Free_Documentation_License}.

Kapitola 2: Cvičení

- Studenti zpracují na téma Piston Compressors powerpointovou prezentaci.

Kapitola 3: Kontrolní otázky

- Can you describe piston compressors?

- Can you give some examples, where they are used?

- Why are portable piston compressors not used very much nowadays?

Kapitola 4: Autotest

- What is the difference between piston compressors and reciprocating compressors?

- Where is the gas compressed?

- How are the pistons usually driven?

- What is a portable compressor?

- Why are portable piston compressors not used very much nowadays?

Lekce 3: Spark-ignition Engines

Kapitola 1: Spark-ignition Engines

Spark-ignition engines are a type of internal combustion engines. Unlike the compression-ignition engines, where the heat resulting from compression ignites the fuel mixture, in spark-ignition engines it is ignited with an electrically produced spark.

Division

There are two types of spark-ignition engines:

Fuel mixture

Because the fuel mixture typically consists of air and petrol (gasoline or gas in American English), they are usually referred to as petrol engines (gasoline engines or gas engines in American English). However, other fuels can be used as well, such as autogas (LPG), compressed natural gas (CNG), methanol, ethanol or hydrogen. Cars in drag racing usually use nitromethane.

Mixing process

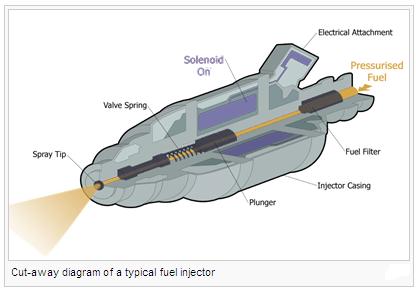

Spark-ignition engines were traditionally distinguished from compression-ignition engines also according to the place, where the fuel is mixed with air. While the compression-ignition engines blend fuel inside the cylinders, in spark-ignition engines it was done outside the cylinders, in a carburettor. However, in modern engines highly pressurized fuel is injected directly into the cylinders, which improves the efficiency of the engines. This process is called gasoline direct injection (GDi).

Vocabulary

spark-ignition engine – zážehový motor

internal combustion engine – motor s vnitřním spalováním

compression-ignition engine – vznětový motor

heat – teplo

compression – stlačení

ignite – zažehnout

fuel – palivo

fuel mixture – palivová směs

spark – jiskra

two-stroke engine – dvoudobý motor

four-stroke engine, Otto cycle engine – čtyřdobý motor

Wankel engine – Wankelův motor

piston – píst

simultaneously – současně

petrol (American English: gasoline, gas) – benzín

petrol engine (American English: gasoline engine, gas engine) – benzínový motor

blend – smíchat

cylinder – válec

carburettor (American English: carburetor) – karburátor

pressurized – pod tlakem

inject – vstřikovat

efficiency – výkon

direct injection – přímé vstřikování

autogas, LPG (Liquefied petroleum gas) – zkapalněný ropný plyn

natural gas – zemní plyn

hydrogen – vodík

drag racing – závody dragsterů

cat-away – průřez

Obrázky a fotografie použité v této kapitole pochází ze stránek {Wikimedia Commons XH http://commons.wikimedia.org}, kde byly zveřejněny pod licencí {GNU FDL XH http://commons.wikimedia.org/wiki/Commons:GNU_Free_Documentation_License}.

Kapitola 2: Cvičení

- Studenti zpracují na téma Spark-ignition Engines powerpointovou prezentaci.

Kapitola 3: Kontrolní otázky

- Can you briefly describe spark ignition engines?

- How can they be divided?

- Can you describe the P-V diagram?

Kapitola 4: Autotest

- Spark-ignition engines are a type of

- In which type of spark-ignition engines do the strokes take place simultaneously?

- What does a typical fuel mixture for spark ignition engines consist of?

- Which of the following is more typical for modern spark ignition engines?

- What does CNG mean?

Lekce 4: Compression-ignition Engines

Kapitola 1: Compression-ignition Engines

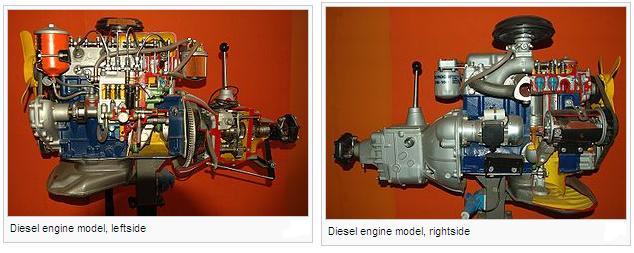

Compression-ignition engine is a type of an internal combustion engine. Because it converts heat into work, it belongs among heat engines. Unlike spark-ignition engines, the fuel mixture is ignited by the heat resulting form the compression of the mixture. The fuel is injected into the combustion chamber in the final stage of the compression.

Operation

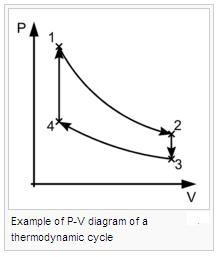

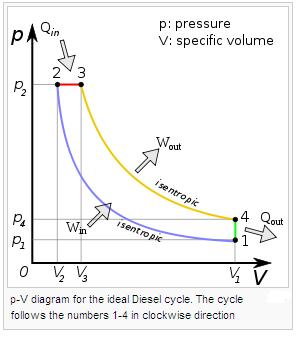

Compression-ignition engines are often also called Diesel engines, after the European inventor and mechanical engineer Rudolf Christian Karl Diesel. It operates using the so called Diesel cycle. The picture on the right shows a p-v diagram for the Diesel cycle, which follows four distinct processes.

- 1 to 2: compression (blue)

- 2 to 3: constant pressure heating (red)

- 3 to 4: expansion (yellow)

- 4 to 1: constant volume cooling (green)

Types

Vocabulary

compression-ignition engine, Diesel engine – vznětový motor

spark-ignition engine – zážehový motor

internal combustion engine – motor s vnitřním spalováním

convert – přeměnit

heat – teplo

heat engine – tepelný stroj

fuel mixture – palivová směs

ignite – zažehnout

compression – stlačení

inject - vstříknout

combustion chamber – spalovací komora

combustion cycle – spalovací takt

four-stroke – čtyřdobý

two-stroke – dvoudobý

motor vehicle – motorové vozidlo

locomotive – lokomotiva

power-to-weight ratio – poměr výkonu k hmotnosti

fuel consumption – spotřeba paliva

clockwise – proti směru hodinových ručiček

Obrázky a fotografie použité v této kapitole pochází ze stránek {Wikimedia Commons XH http://commons.wikimedia.org}, kde byly zveřejněny pod licencí {GNU FDL XH http://commons.wikimedia.org/wiki/Commons:GNU_Free_Documentation_License}.

Kapitola 2: Cvičení

- Studenti zpracují na téma Compression-ignition Engines powerpointovou prezentaci.

Kapitola 3: Kontrolní otázky

- Can you briefly describe compression-ignition engines?

- How can they be divided?

- What are the processes of the diesel cycle?

Kapitola 4: Autotest

- Compression-ignition engines are a type of

- How is the fuel ignited?

- When is the fuel injected into the combustion chamber?

- What are the types of compression-ignition engines?

- Why do compression-ignition engines belong among heat engines.